What do Chemical Engineers do?

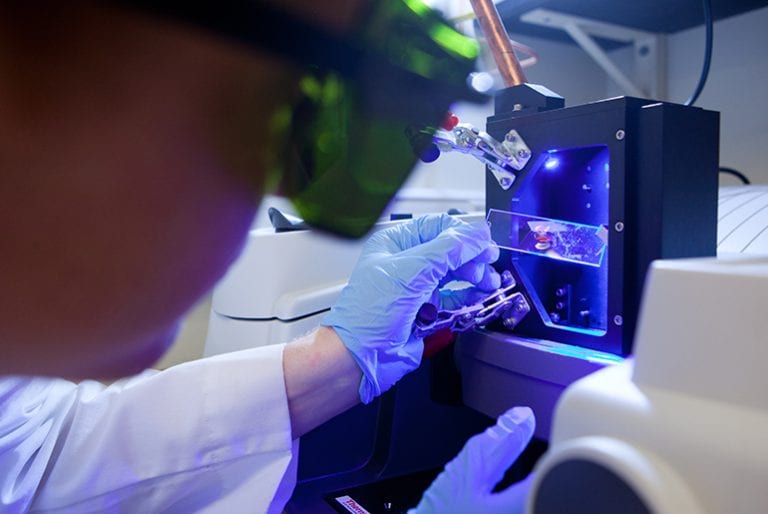

We can do just about anything, from large scale production and management to microscopic research. We design and manage all types of processes that involve chemically and physically transforming matter to make products environmentally friendly and economically viable. We innovate biotechnology and engineer microorganisms to synthesize new drugs, novel protein therapeutics, biocompatible materials, and whole-cell biocatalysts. We develop more sustainable energy resources or solve challenging global problems, and use supercomputers and computational modeling and data science to redefine the frontiers of chemical engineering.

Michigan Engineering | University of Michigan

Michigan Engineering | University of Michigan