What do Mechanical Engineers do?

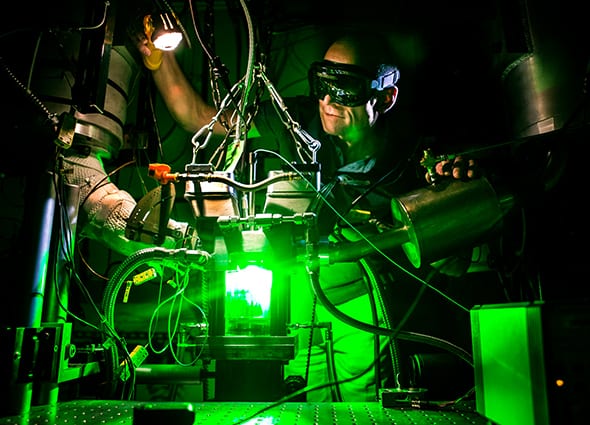

We design and build the products that support our society. From prosthetics to cars to planes to robots- everything that you touch, we have worked on. We can work closely with machine parts, construct intricate micro- or nano-scale systems, or perfect a final product with testing and optimization techniques, all using our foundational knowledge of how mechanical systems work.

Michigan Engineering | University of Michigan

Michigan Engineering | University of Michigan